Laser Cutting Services

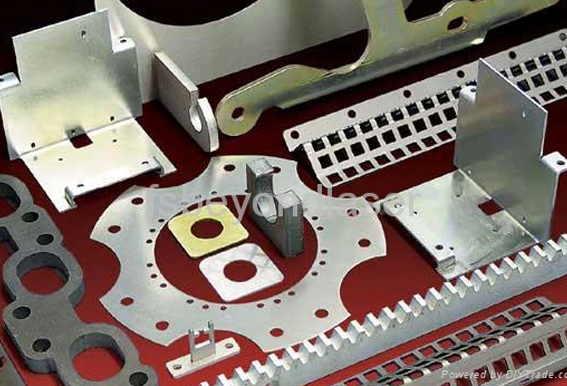

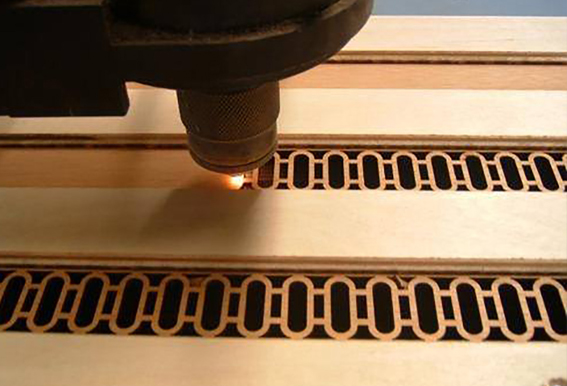

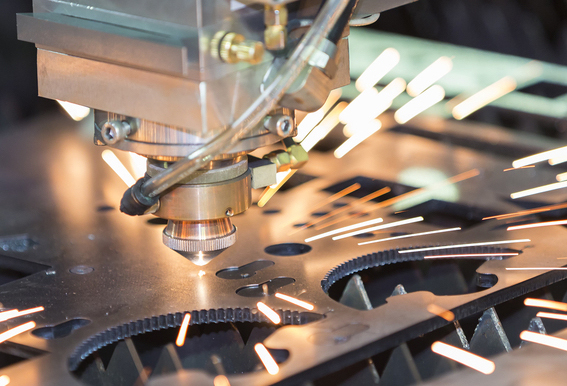

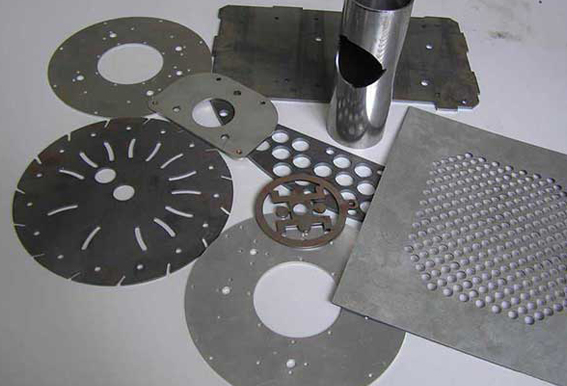

We are engaged in the business of providing highly effective services for Laser Cutting. These lasers are quite advanced and their intense focus make designs in a repetitive pattern. The precise finishing and accurate dimensions of these patterns has lead to wide acknowledgement and repeated demand from the patrons. For that, we using Trumpf TruLaser 3030 leading laser cutting machine, which enables us to cut sheet metal parts and pieces of any shape, ensuring 100-percent repeatability. Thanks to the high quality of the edge cut, parts requires no further finishing, Makes it possible to use the latest software , which allows us to achieve a very high cutting accuracy of up to 0.1 mm.Using advanced software, we can utilize our materials to the maximum extent and optimize the laser cutting process.

The Tru Flow laser, which is robust and reliable, will create extremely smooth cutting edges which generally do not require post-processing. Due to compact machine dimensions and a simple operating concept, the TruLaser 3030 is the perfect overall package for the production of your laser-cut parts.

Technical parameters:

Laser Cutting Services

The price of laser cutting is estimated depending on the complexity of a given piece. Upon the Client's request, we create technical documentation for the purposes of the order. A piece can be also valued on the basis of technical drawings submitted by the Client (*.dwg and *.dxf files are required for this purpose).

Advantages of laser cutting as opposed to other machining types